Kirkby Moorside

KIRKBYMOORSIDE: Civil private airstrip

Note: Unit 2025 I still hadn't found out if this site was spelt as one word or two. The answer is both, the two word spelling preceeding the one word version.

IMPORTANT NOTE: This location was previously known as WELBURN HALL prior to WW2. See seperate listing for more info.

Note: All these pictures were obtained from Google Earth ©

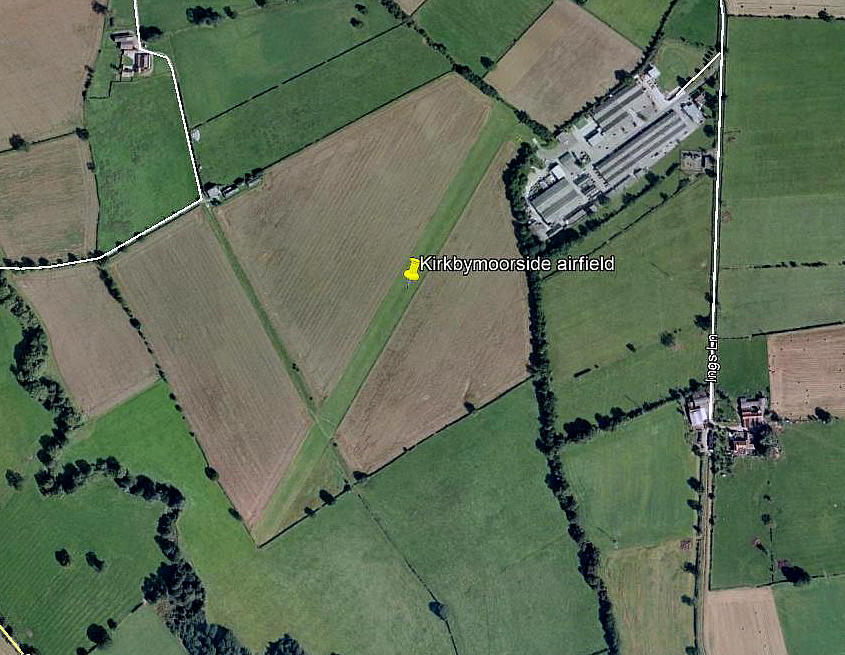

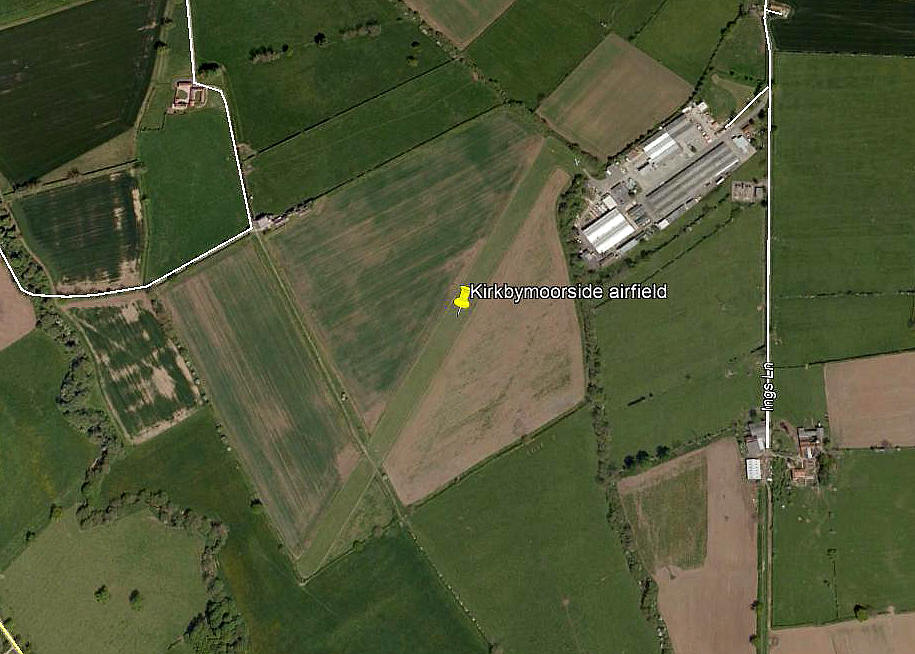

The fourth picture shows that although disused in 2015, the runway is still visible. A year or two later all traces had gone.

Note: Pictures by the author.

Operated by: 1980s: Slingsby Engineering Ltd

2001: Slingsby Aviation Ltd

Location: 1nm S of Kirkbymoorside town centre

Period of operation: 1934 to 2013? (Some say 1931 - see below)

Manufacturing: Slingsby (also known by a succession of names for this company starting with Slingsby, Russell & Brown, Slingsby Sailplanes (1939), Slingsby Aircraft, Vickers-Slingsby (1969), Slingsby Engineering and lastly Slingsby Aviation

Runway: 2000: 04/22 735x20 grass

2009: 03/21 720x20 grass

NOTES: The first Slingsby gliders were built in Scarborough but in 1934 they moved to new premises at KIRKBYMOORSIDE. The series of now famous gliders included the Kite, Kadet, Tutor and Sedburgh (first flown in 1944), and the Petrel, Swallow (first flown in 1957). The Capstan followed (first flown in 1961), and the Dart (first flown in 1963), was succeeded by the T53 (first flown in 1967). Last but certainly not least were the Kestrel and Vega, the latter first flown in 1977.

AN ACCOUNT

In his excellent biography, Amy Johnson - Enigma in the Sky, author David Luff has this account: "One of the founder members of the gliding club at Scarborough was Fred Slingsby, a Yorkshireman who went on to establish his own sailplane factory at Kirbymoorside (sic?) in 1931, the first of its kind in the UK. As soon as he knew of Amy's involvement with the sport he offered her the permanent loan of one of his single-seat Kirby Kite sailplanes."

"From then on she was to be seen arriving in her Ford roadster at clubs all around the country. She would arrive at Dunstable, Long Mynd, Sutton Bank or Camp Hill in Derbyshire with her dismantled sailplane tucked neatly into a trailer. The Slingsby product was a fully aerobatic plane, and Amy loved nothing better than to be catapulted from a hilltop into an up-current and put her machine's gracefully tapered wings into a loop over the patchwork-quilted landscape beneath her."

"She was once quoted as saying: 'Sailing smoothly and gently through the sky in a glider was the next best thing to graduating as an angel'."

THE WW2 ERA

In WW2 Slingsby Sailplanes manufactured Avro Anson parts plus 13 Hotspur and 18 Hengist gliders. The company was also the UK design authority for the WACO Hadrian glider. But, their main activity was producing Kadets and Tutors for the ATC and much of this production was sub-contracted. Well over 100 Grasshopper primary gliders were also built.

THE BAYNES BAT

Perhaps one of the oddest concepts in WW2? Mr L E Baynes designed a 'flying tank' in 1941 that could be towed to a battle zone, then released to glide in. In 1943 it appears that Slingsby built a 1/3 scale model which first flew here in July. It was then taken to the Airborne Forces Experimental Establishment at SHERBURN-in-ELMET and appears to have flown quite well. However, the concept was not progressed.

A FIRST?

The company was perhaps the first British company to introduce the motor-glider concept to the UK? The Type 29B Motor Tutor G-AKEY first flight taking place in June 1948. It seems another attempt was made twenty years later with the Capstan G-AWDV in 1968. However, it seems they failed to make the concept marketable.

THE NIPPER EPISODE ETC

In 1966 Slingsby acquired a contract from Nipper Aircraft Ltd to build the Tipsy Nipper III and some twenty nine examples were built. It is well known that a large number of successful Slingsby gliders were built here and in later years the T.67 powered types too, based on the wooden Fournier RF-6B design. Indeed it appears the first of ten, the T.67A G-BIOW were wooden and assembled from French-built components.

THE T.67

Slingsby then decided to completely re-engineer the Fournier RF-6B design for composite construction and produced versions with a series of more powerful engines. Starting with the T.67B, T.67C, T.67M, T.67 M-Mk.II, M200 and ending with the M260-T3A. Having met Mr Fournier I can relate that he was very unhappy with what Slingsby were doing with his design. Indeed, he made no secret of the fact that he had never designed this aircraft to operate at such weights and with such powerful engines. The fact of the matter appears to be that Slingsby had actually done a very good job of developing the design, but along the way had made a just a small and very basic engineering/design mistake - and it was this aspect which has killed so many pilots.

These composite types produced a horrendous fatal accident record but were always still allowed to fly in the UK! The USAF brought one version and having realised just how dangerous they were not only grounded them, it appears they burnt them. One has to ask just how effective the highly complex certification procedures really are when faced with common sense statistics? I sent a letter to the CAA asking just how many have to die before the type is grounded having very nearly losing my life in one? Needless to say I did not get an answer and pilots kept on being killed.

I was at the airshow at SHUTTLEWORTH (OLD WARDEN) and saw Pete Clarke, then the Slingsby test pilot killed when demonstrating a T.67. The official AAIB report was a ‘white-wash’ affair and the type kept on flying and killing other pilots. Eventually the problem was found, and exactly as I had predicted, but nothing was said or published as far as I know.

The problem, without any doubt, was that the rudder-bar on the right-hand side could catch behind a bracket that carried a cable into the engine compartment, and when in a spin the pilot on the left-hand side could not free this, resulting in full rudder being applied and not capable of being centered. Slingsby of course denied this, but the tolerance gap they said was acceptable was ridiculous. Just a small amount of wear and/or airframe distortion could cause this jam.

In my case, just learning to fly, a large and strong instructor kicked the rudder bar free - but insisted that I had 'frozen' at the controls. I of course knew this wasn't true, but the AAIB accepted his explanation after the same aircraft spun into the ground a week later with fatal results for both pilots. One of whom was the owner and CFI of the flying school.

ON THE DAY

Once news came in of the aircraft disappearing from radar, my instructor said we should do a search for the aircraft, suggesting we'd find it in a field after engine failure. Instead we found the crash site and the burnt-out remains.

As you might imagine, it took quite a while to get over this, before accepting that such things will happen, and realising that I still wanted to learn to fly - this time at Wycombe Air Centre on Cessna 152s.

SPOTTERS NOTES

In 1977 the Slingsby T-59D Kestrel G-BBVC, T-59H Kestrel G-BDZG and T.65A Vega G-BEJJ, (apparently all registered to Vickers Ltd ), were based here.

Ellen Jones

This comment was written on: 2021-01-29 20:52:06I also witnessed the crash at Shuttleworth- I was 7 at the time (32 now) and still have the memory of that plane corkscrewing into the trees imprinted on my memory. I've read about the official conclusions. It's interesting to see a different perspective on the cause.

We'd love to hear from you, so please scroll down to leave a comment!

Leave a comment ...

Copyright (c) UK Airfield Guide