Cowley

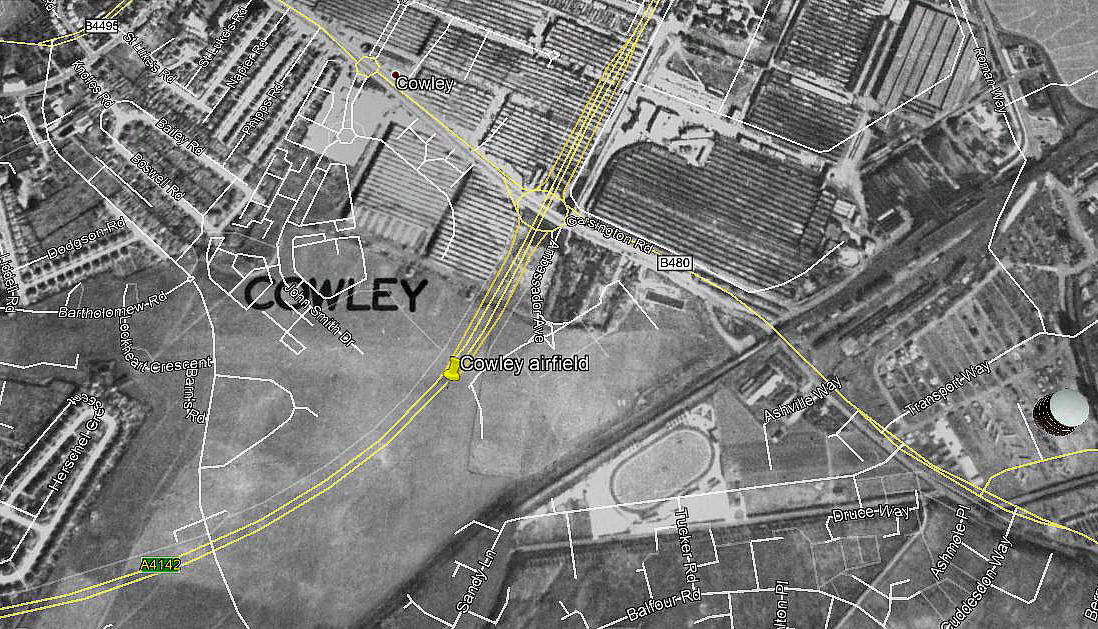

Note: This map only gives a rough idea of the position of the Cowley car plant. If anybody can kindly provide a more exact location for the airfield used, this advice will be most welcome.

COWLEY: Private company airfield

Note: This picture was obtained from Google Earth ©

In early 2020 I was kindly contacted to point out that this picture shows traces of the 'airfield' at Cowley. Am ashamed to say I then lost his contact details and name. Please contact me again if you should see this listing.

Operated by: WW2: Morris Motors. Also No.1 Civilian Repair Unit

Location: Roughly 1.5nm SE of Oxford city centre

NOTES: My first notes were: In WW2 Morris Motors produced at least several hundred DH.82A Tiger Moths here. In fact, once de Havilland at HATFIELD (HERTFORDSHIRE) had been instructed to commence full scale of the Mosquito, Tiger Moth construction had to be moved elsewhere. The Ministry of Aircraft Production decided to move all UK Tiger Moth production from HATFIELD to Morris Motors at COWLEY. See HATFIELD for more info.

MORE INFO

I have, amongst other sources, mostly Stuart McKay to thank in his excellent book Tiger Moth from which I’ll quote: “When UK Tiger Moth production was switched to Morris Motors at Cowley early in 1940, the first aircraft were assembled on link driven production lines using parts supplied by de Havillands. Running in parallel with military vehicle manufacture, the motor industry attempted to apply the same techniques to light aeroplane construction, and a sour atmosphere developed between the Morris management and resident DH technical representatives concerning the quality of some of the early aircraft.” Can this be hardly surprising – and indeed, a foreseeable consequence to be expected?

I would think that to go from vehicle manufacture to aircraft manufacture in such a sudden jolt, which was achieved in a very short time span, and considering the highly constrained and conservative workplace practice mostly employed in those days, a considerable degree of applause to all involved is now deserved.

“Using a DH built fuselage as a pattern, Morris completed their first Tiger Moth in April 1940. The aircraft was taken by road to Hatfield for a thorough inspection where 67 major complaints were listed, although Morris countered by arguing that the aeroplane had been built to Hatfield supplied drawings!” Something I can easily believe having heard many a story about degrees of ineptitude at de Havilland over many years, but in fairness, these peple at Cowley were expected to deal with a totally different culture, and no previous experience of aircraft production.

A FLYING SITE

But, returning to my quest to discover flying sites, Stuart McKay has this to add: “The aircraft were returned to Morris for rectification and eventually taken by road to Witney aerodrome for its first flight. Subsequent Cowley aeroplanes were flown out of a small field behind the assembly shops.” Not exactly a precise location of course, but close enough for the purposes of this Guide.

Also, in his book Tiger Moth Stuart McKay adds this: “….a field large enough to permit operation of Dominies (My note: The military version of the DH.89 Dragon Rapide), and Spitfires. The Spitfires were routed to Cowley for repair and the Dominie and occasional Proctors acted as taxis for the ferry pilots.”

WW2 TIGER MOTH PRODUCTION

Here again I have Stuart McKay to thank in his book Tiger Moth: “With the exciting new Mosquito ordered into full production yet the continuing and increasing need for still more Tiger Moths, there developed an inevitable conflict in the allocation of resources. In 1940, the Ministry of Aircraft Production decided to transfer all UK Tiger Moth manufacture into the hands of the motor industry.”

Can we just think about this for a moment? From making cars, together with the re-training and re-tooling etc, this was achieved with astonishing speed.

“Morris Motors was contracted to establish a line at Cowley near Oxford, absorbing a number of incomplete Hatfield supplied airframes with which to plot their learning curve.”

I think we must remember that both car and aircraft manufacture in those days needed the skills of many highly capable engineers – it was not just an assembly of components sort of business. “Alongside military vehicle construction, Morris Motors quickly organised an assembly track for Tiger Moth fuselages which progressed through tunnel type surroundings under the influence of a chain link drive. It didn’t work. This typical mass production style was later changed and relocated in more spacious premises where fuselages were built on individual dollies; hand propelled along guide rails to the next stage in their development.”

This appears to indicate a certain degree of flexible thinking, even under duress in a full-out war scenario.

“Nearly all components used at Cowley were made in-house although some wooden parts were supplied by outside contractors, crudely nailed and glued perhaps, products of the nation’s cottage industrialisation.” This last comment I cannot quite understand. From over a century before the skill and finesse involved in bespoke furniture production, (mostly of wood of course), was well established. And, as I understand it, it was these craftsmen who had been drafted in to assist aircraft production?

“Engines, instruments, electrics, wheels, tyres and propellers were bought in to take their allotted places on the airframes, assembled almost exclusively by female labour.” As pointed out elsewhere in this Guide, it really is a matter of national disgrace that, in the UK, (and obviously widespread elsewhere globally), that parity of the sexes in the workplace, even in the 21st century, still has a long way to go.

TOTAL TIGER MOTH PRODUCTION

In February 2022 I was kindly contacted by Mr Richard Sellers-Smith who tells us that by the end of production in 1945, 3,433 Tiger Moths had been built here.

JOHN MICHAEL RICHARDS

This comment was written on: 2019-01-21 12:49:23IS THERE ANY INFO ON THE ROLE OF RAF GROUP 43 MAINTENANCE COMMAND WRT COWLEY.GROUP43 WERE BASED AT MERTON AND MAGDALEN COLLEGES OXFORD AND I BELIEVE DEALT WITH THE ADMINISTRATION OF COWLEY PRODUCTION -J M RICHARDS-SON OF A GROUP 43 MEMBER

David Pittaway

This comment was written on: 2020-04-17 20:54:26The Cowley (Oxford) airfield site was located in what is now know as Bartholomew Road. Cowley St James Primary School mentions the airfield site in their signage.

Clive Dalzell

This comment was written on: 2020-05-29 08:58:11If you have Google Earth (you can download it for free) you can view an aerial image of the site and airfield taken in 1945 using the date slider. It was to the south of the factory opposite the Blackbird Leys dog racing track and on the map you can still see a faint outline of the runways used.

Clive Dalzell

This comment was written on: 2020-05-31 10:29:46As already mentioned in the main text, Cowley was also one of the Civilian Repair Units for spitfires during the war. Maybe there were RAF engineers to assist them based at Cowley as well? It would certainly indicate there was a very high level of skill amongst the workforce to not only produce Tiger Moths but also be trusted to repair a valuable fighter aircraft.

Geoff Sutton

This comment was written on: 2021-05-31 22:25:27I live in Headington, not far from Cowley airfield and once heard a tale, true of course, that a Lancaster landed at the airfield by accident. The pilot was told he had to get the aircraft out again and so it was stripped of all excess weight. It was taken to the longest "runway", the pilot put aboard, engines started and then it took off, just clearing the Barns Road bridge over the railway at the southern corner of the airfield.

We'd love to hear from you, so please scroll down to leave a comment!

Leave a comment ...

Copyright (c) UK Airfield Guide